High strength Western Europe bow top fencing suppliers Western Europe

Special welded 1.5 * 1.2m roll top fence applied to Australian Industrial Factory

BRC Fencing is a Special welded panel, made of high strength steel. It can be hot dipped

galvanized material, which is better durability. For security reasons, it applies to Play Ground,

Stadium, Housing Estate, and so on. BRC Fencing protects some public places. The DB Fencing

ensures high quality and good after-sales service.

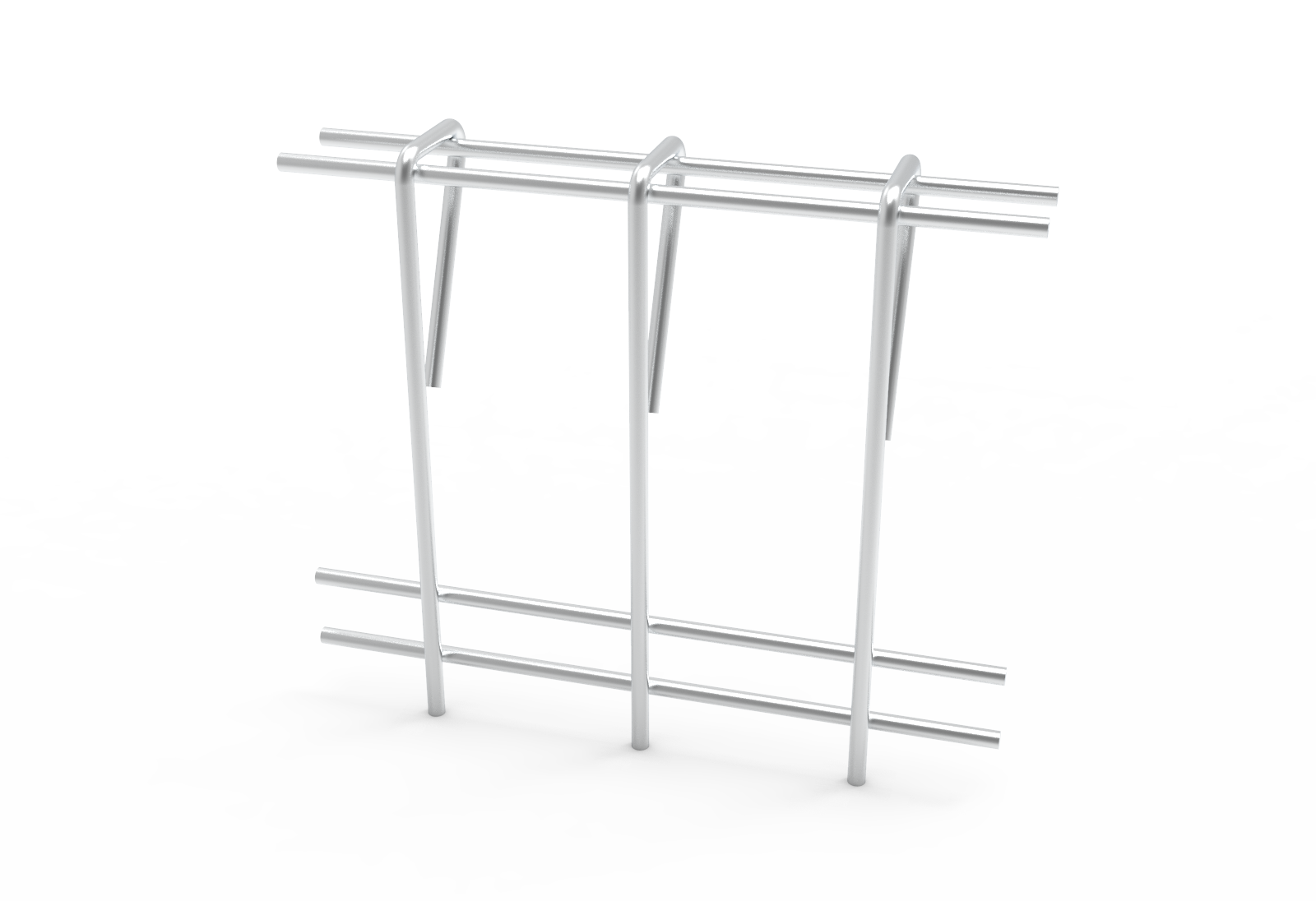

Detailed description of BRC Fencing

The width of the panel is 1000mm to 3000mm, and the height 900mm to 2400mm.

The diameter of steel wire is 3.0mm to 6.0mm. The mesh size is 50 x 100, 50 x 150,

50 x 200, 75 x 200, 75 x 300, 100 x 200, 100 x 300mm. You can choose your own customized

color. Panel material is low carbon steel wire Q195, Q235. The surface treatment is hot dipped

galvanized and powder coated.

|

Panel width |

From 1000mm-3000mm |

|

|

Panel height |

From 900mm-2400mm |

|

|

From 3.0mm-6.0mm |

||

|

Mesh size(mm) |

50 * 100, 50 * 150, 50 * 200, 75 * 200, 75 * 300, 100 * 200, 100 * 300 |

|

|

Material: |

low carbon steel wire Q195, Q235 |

|

|

Surface treatment |

Hot dipped galvanized (505 g/m2). |

|

|

Color |

available any RAL. |

The panel has no sharp or raw edges, and the roller roof is suitable for safety applications.

Detailed description of post and clamp system

BRC Fencing contains a post and clamp system, which is divided into square pipe and

round pipe. The thickness of the column is 1.5mm, 2.0mm and 2.5mm. The surface treatment

of the product is electric galvanized and hot dip galvanized with polyester powder coating,

effectively prevent the rust of the product.

Production Process of BRC Fencing

STEP 01

First weld low carbon steel wire to design dimension panel, then need special bending machine

to make rolling top and bottom.

STEP 02

Then a professional bending machine is required to make roll tops in both the top and bottom.

STEP 03

The fence is designed to have a triangular roll on the top and bottom of the fence make it more

strong and tough.

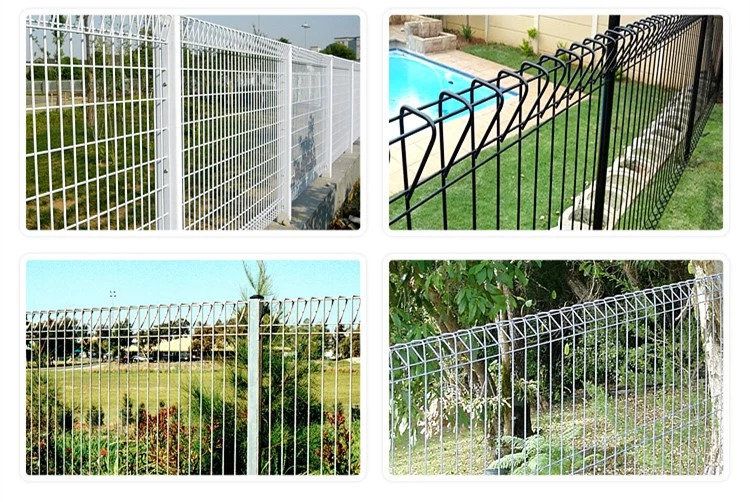

Applications of BRC Fencing

BRC Fencing, also called roll top fence, is very strong, not easy to bend. In addition, it helps prevent

anyone from easily climbing over the fence to the protected area. It is widely used by reputable real

estate developers, industrial factories, engineering companies, farm owners and government departments.

It also applies in the following ways.

Army Camp, Gated Security, Prison, Industrial Factory

Play Ground, Stadium, Housing Estate, Detention Centre

Carpark, Public Hall...

Benefits of BRC Fencing

High quality galvanized coating allows roll top fence users no worries, because it is different from

many other low-carbon steel fences. Hot dip galvanizing is not easy to rust in a short time. Therefore,

low maintenance or free maintenance for a long time to give users a good product experience

Suitable where safety is a consideration

Aesthetic appearance

High rigidity

Excellent through vision

Wide range of colour options

Available as a complete system

![]()

Features of BRC Fence

Not get rusted easily in a short period of time

Aesthetic appearance

5.0mm wire makes High rigidity and better safety

Excellent through vision

Wide range of colour options

No sharp or raw edges

Compliant with BS 1722 Pt. 9

Security Fixings

Welded Construction

Hot Dip Galvanised to BS EN ISO 1461

Polyester Powder Coated option